Fabric Discovery Center: 73 Resources found

| Air Permeability Tester SDL Atlas MO21A Please contact mark_keene@uml.edu for further information on this instrument.

The air permeability tester is used to test the resistance of fabrics (woven, knitted and nonwoven textile materials) to the passage of air. The specimen is placed in the test area and clamped in place and the test automatically starts. The tester complies with ASTM D737, Standard Test Method for Air Permeability of Textile Fabrics. The test head is 20 cm2. Minimum sample size 13cm / 5" square or round.

Allow 15 minutes for training.

| Industry Rates

|

| Balance Entris Ancillary Equipment

No Additional Charge

High-precision laboratory balance to determine the mass of materials in liquid, paste, powder, or solid form. The balance has a rectangular weighing pan with a 6,200 g (about 13-lb) weighing capacity.

| |

| Carding Machine Mesdan 337A Miniature carding machine designed to produce an homogenous sample of fibers of different color and/or nature.

It can process both short and long fibers.

Self-cleaning system to avoid dirtying of the sample.

Delivery speed: 10-15 m/min.

Average production: 4kg/hr.

Minimum quantity to be processed: around 5 grams of fibers.

Working width: 500 mm (25”).

| Industry Rates

|

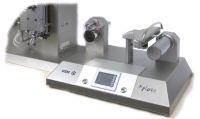

| Cast Film Pro Line Xplore IF YOU WANT TO USE THE CAST FILM PRO LINE IN CONJUNCTION WITH THE MICRO-COMPOUNDER, PLEASE RESERVE THE UNIT FOR THE SAME TIME PERIOD.

The Cast Film Pro Line is designed to work in conjunction with the Xplore micro-compounder for processing various polymer materials and additives into film samples. The CFPL involves a heated film die that is installed on the micro-compound along with a system consisting of an air knife and rollers, which affect film properties such as thickness, necking, haze, surface roughness, crystallinity, etc. The air knife controls the film necking as material is extruded through the heated die. The take-up roll (first roll) has adjustable speeds from 100 mm/min up to 5000 mm/min with increments of 1 mm/min. This roll can be air cooled by compressed air for additional processing control. Sequentially, the transport roll (second roll) comprises of one roll with another roll on top to apply mechanical pressure on the film samples to minimize slipping. Lastly, the winder roll (third roll) is torque controlled to collect the film samples evenly with adjustable increments of 1 Nm.

| Industry Rates

|

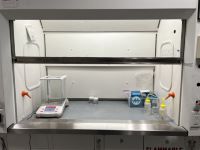

| Chemical Safety Hood Mott Manufacturing Standard chemical safety hood for use when working with chemicals to safely exhaust fumes, gases, etc. Please book this hood whenever using hazardous chemicals. Hourly rate includes a hazardous waste removal and disposal fee.

| Industry Rates

|

| Clothes Dryer, AATCC Compliant, Vortex M6D SDL Atlas The Vortex M6D is designed to work in conjunction with the Vortex M6. The instrument is equipped with a quiet, efficient blower system that can generate airflow up to 220 ft3 per meter to test samples quickly: reducing operating costs. Additionally, it provides efficient heating with 5,350 Watts. Material design of the instrument comprises of durable galvanized steel cylinder with an 18-pound capacity. Mechanical controls are implemented to control testing conditions as well as ensure reliable and repeatable testing. | Industry Rates

|

| Clothes Washer, AATCC Compliant, Vortex M6 SDL Atlas The Vortex M6 is a commercial grade top loading laundry machine that is designed to accurately wash textiles consistently. It has capabilities to control the bath temperature, water fill, agitation, and spin. The instrument is also equipped with a controller to set custom program profiles to test samples up to 72 hours. The Vortex M6 construction is designed to meet AATCC Monograph home laundry requirements with the heavy-duty variable speed motor, non-locking lid with braking system, porcelain-coated steel wash tub, and a stainless steel basket. | Industry Rates

|

| Crockmeter/Rubbing Fastness Tester, M238AA (Model CM-1) SDL Atlas The Crockmeter tests the color transference from one surface by dry or wet rubbing manually between the two surfaces. Additonally, the crockmeter also performs scuffing, wet/dry abrasion, flexing, powdering dry-cleaning, ink abrasiveness The test specimen is enclosed into the bottom holder and a test cloth is clamped onto the rubbing finger. The test cloth applies a force of 9 newtons onto the test specimen. The stroke length can be adjusted to 50, 76, and 104 mm (2, 3, and 4 inches) in order to accomodate different specimen lengths. | Industry Rates

|

| Digital Microscope Olympus DSX1000

The Olympus DSX1000 is a digital microscope used to observe and measure a variety of samples, including electronic components and metal materials. The microscope requires little training to use; simply place your sample and easily perform a series of operations from 3D observation to measurement and reporting.

The DSX1000 microscope meets a wide range of observational and analytical needs in a single unit while improving the inspection workflow. An expanded lineup of lenses covers a 20-7,000X magnification range. Users can also take advantage of the microscope’s six observation methods: brightfield, darkfield, mixed, polarizing, oblique, differential interference contrast (DIC) and advanced functions such as contrast up, HDR glare, HDR texture and depth of field focus to observe and measure a variety of objects. For example, techniques are available to highlight irregularities on a sample surface or emphasize contours. The observation head and stage can each be freely adjusted ± 90° to accommodate samples with many shapes and to view the samples from all angles. In addition, newly developed algorithms can be used to acquire detailed 3D images approximately ten times faster than conventional digital microscopes.

| Industry Rates

|

| Dyeing Machine Datacolor Ahiba IR Pro Accurate laboratory fabric sample dyeing. The Ahiba IR moves the beakers in a circular rotation with advanced infrared heating technology. Touch screen controller. Temperature range, 20-140C. Speed, 5-50 rpm. Manual dosing. Programable. Eight 500 cc sample beakers.

| Industry Rates

|

| Fabric Cutting Table Gerber DSC2600 Cuts intricate shapes with great accuracy and edge quality, without sacrificing speed. Pneumatic vacuum table with shutoffs for single-zone or dual zone vacuum. Laser pointer for precision pointing.

CutWorks® software automates part/ply placement for enhanced throughput and material utilization. Requires dxf file type. Cutting Area:57"x 110"

| Industry Rates

|

| Fabric Stiffness Tester, M003B SDL Atlas The Fabric Stiffness Tester determines the fabric stiffness by evaluating the resistance to bending for the sample. The fabric stiffness is dependent on the mass, fiber properties, fabric construction, and fabric treatments. Sample testing for this instrument include cutting a rectangular strip of the sample and situating it on top of the horizontal platform, which has a section that is inclined at a 41.5 angle so that the fabric may bend by its own mass. The bending length parameter is determined by correlating the fabric position to the scale on the instrument. Flexural rigidity and bending modulus can be calculated based off the bending length, mass, and unit area of the sample. | Industry Rates

|

| FDC Technical Assistance | Industry Rates

|

| Fiber Conditioning Unit Xplore The Fiber Conditioning Unit is a standalone unit intended to post-process any mono-filament fiber. This instrument uses two winders set at different speeds with a heating chamber situated in between to elongate the fiber in order to alter its material properties. | Industry Rates

|

| Fiber Spin Line Xplore IF YOU WANT TO USE THE FIBER SPIN LINE IN CONJUNCTION WITH THE MICRO-COMPOUNDER, PLEASE RESERVE THE UNIT FOR THE SAME TIME PERIOD.

The Fiber Spin Line is a modular system that works in conjunction with the Xplore micro-compounder to produce mono or multi-filament fiber. This system has two configurations that incorporate different accessories to accommodate the process to properly collect single or multi-filament fiber. Only a few grams of material suffice in producing ample fiber samples. Control over processing parameters, such as screw speeds, temperature profiles, quench air, draw ratios, and other settings, determine the inherent fiber properties. For the multi-filament fiber setup, it is capable of extruding 12 individual filaments. | Industry Rates

|

| Film/Blade Coater MTI Corporation MSK-AFA-II-VC-FH Auto Film Coater w/Vacuum Bed, Heatable up to 120°C (12"W x 24"L) & 250mm Doctor Blade

Maximum Coating Area: 250mm (9.8") W x 530mm (20.8") L

Traverse Speed: 10-100 mm/sec variable

Stroke Length:10 (0.4") - 530 mm (20.8") adjustable by using Adjustable Position Switch

Micrometer adjustable film applicator, film thicknesses > 10 microns.

| Industry Rates

|

| Furnace Gesswein 913 Programmable Burnout Furnaces

Dimensions of Chamber: 13"Wx13"Dx9"H

Max Temperature: 1,700°F / 920°C

| Industry Rates

|

| Gelbo Flex Durability Tester 1 Document AvailableVinatoru Enterprises GFT392 Complies with ASTM test method F392

This instrument has been designed to determine the flex resistance of the flexible barrier materials by applying repetitive strain. Pinhole formations are the criteria for measuring failure and are determined by use of colored turpentine and allowing it to stain through the pinholes onto a white backing. Specimens of flexible materials are flexed at standard atmospheric condition (23°C / 73°F and 50% relative humidity). The flexing action consists of a twisting motion combined with a horizontal motion, thus, repeatedly twisting and crushing the film. The frequency is at a rate of 45 cycles per minute. There are 5 test conditions to choose from. One may choose a test cycle that simulates real conditions from partial flex for 20 cycles to full flex for 2700 cycles. Sample size 8"x11" (200 x 280 mm)

| Industry Rates

|

| Gerber Design Station PC with Gerber Accumark 2D Fashion Software for design, development, grading and marker-making

GTCO, Model SL6 4460, Large Format Digitizer, 44 x 60in/1,117.6 x 1,524 mm, Active Area. Digitize patterns into the Accumark Software

Graphtec, Model CE7000-130AP, Cutting Plotter, Maximum width 50". Cut or plot design patterns

| Industry Rates

|

| Humidity Chamber Sheldon HC6-2 Interior Dimensions: 20” wide x 14” high x 15” deep

The Model HC6-2 Humidity Chamber is designed to maintain temperature from ambient +5°C to 100°C. The Humidity System is designed to control humidity from 40% to 80% between the temperatures 40°C to 100°C.

| Industry Rates

|